Kitchen oil fume purifier

Overview

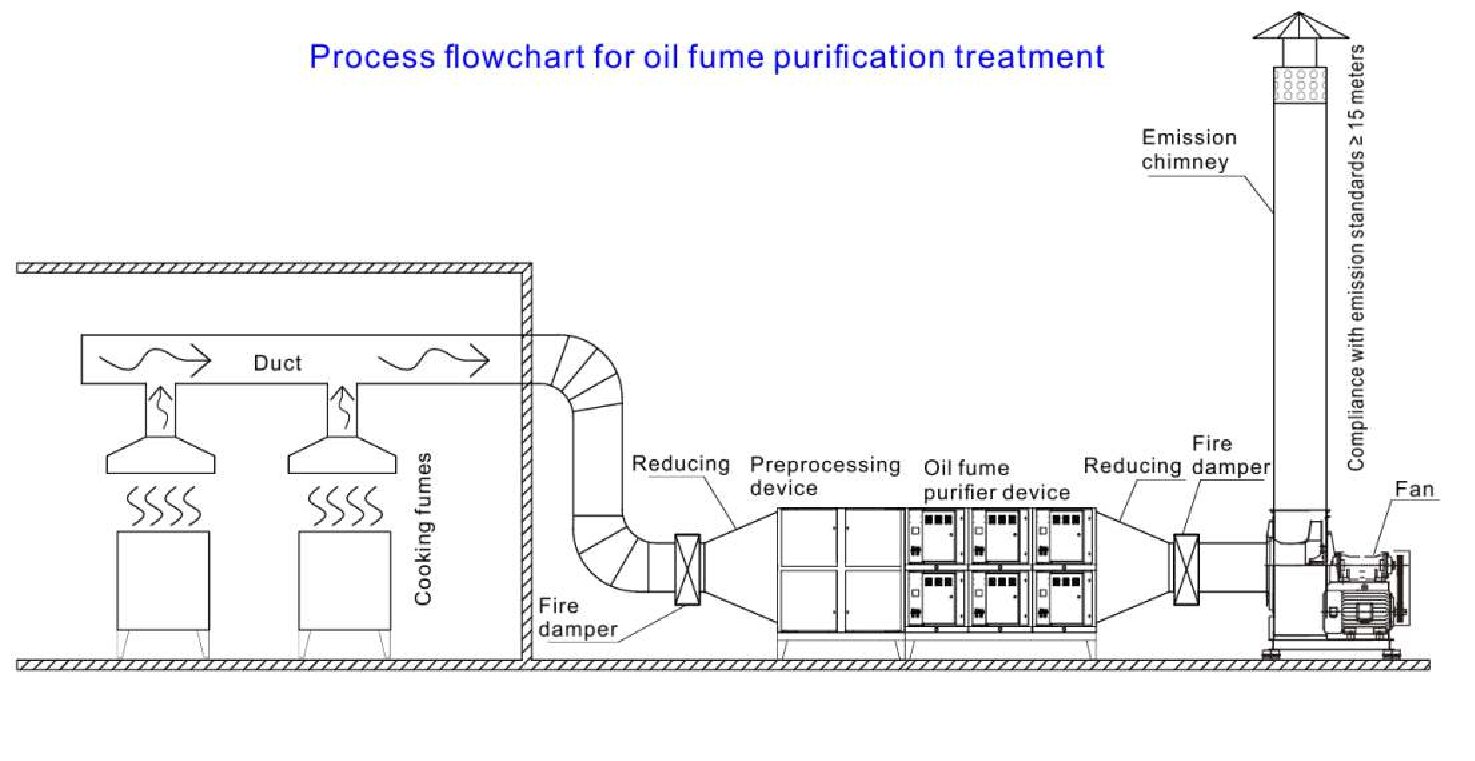

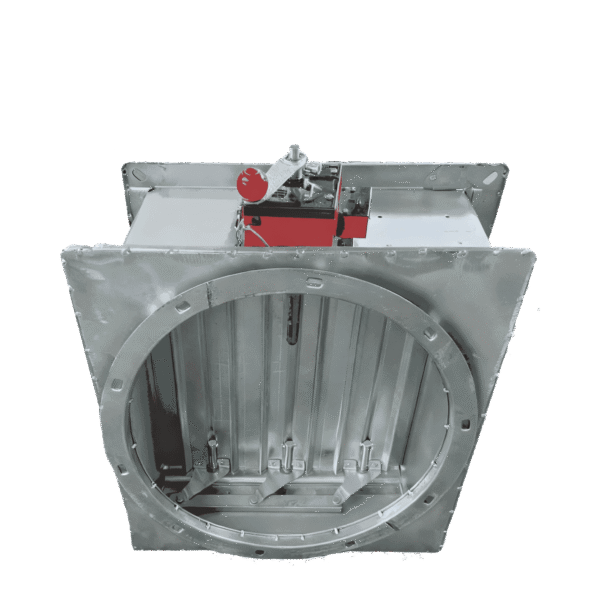

The kitchen oil fume purifier system and industrial oil fume purification system use a combination of physical mechanical filtration and electrostatic adsorption technology to purify and collect oil mist with different air volumes. According to different working conditions and oil mist composition

Different preprocessing devices are used separately, mainly including condensing devices and defogging devices. The condensing device is mainly designed for the purification and cooling of high-temperature oil mist before collection. Before passing through the oil fume purifier, the oil mist must be cooled to below 60 ℃ for purification and collection. The defogging device is mainly designed for high oil mist concentration or high water vapor composition in oil mist. Before passing through the oil fume purifier, the oil mist concentration must be reduced and the defogging treatment must be carried out. After pre-treatment, the particle range of the oil mist is controlled within 0.01um-3um, the temperature is controlled below 60 ℃, and most of the water vapor is filtered out to achieve the best electrostatic adsorption effect.

Application field

The kitchen oil fume purifier system is used for purifying the large amount of oil fume and water vapor generated during cookingIndustrial oil fume purifier is suitable for quenching heat treatment, forging, cold heading machine processing, fastener processing, vacuum pump oil mist, wire rolling machine oil fume, casting machine processing, CNC machining center centralized oil mist treatment, asphalt smoke, PVC rubber production, electronic factory and other oil fume and oil mist exhaust gas treatment.

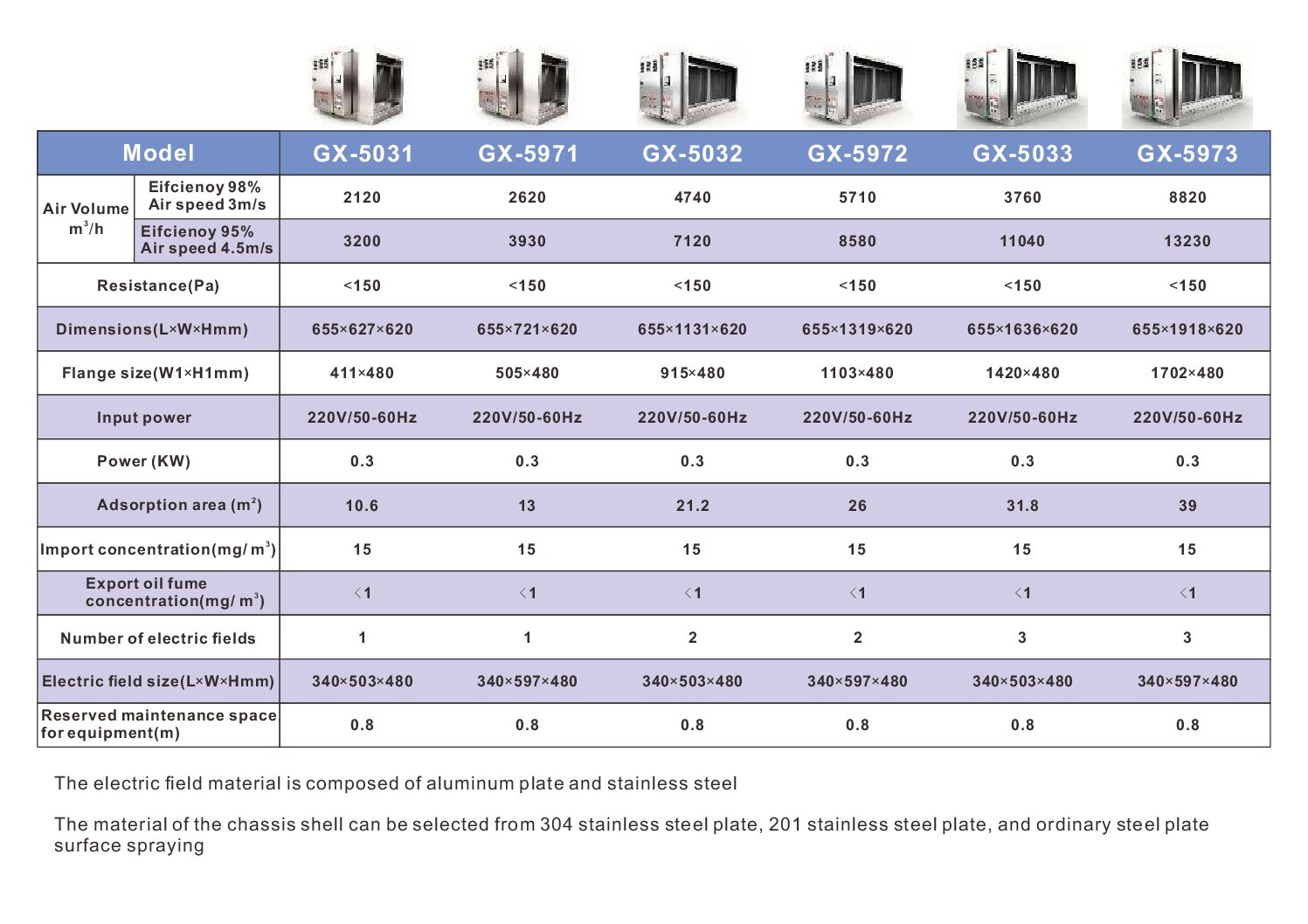

Specification

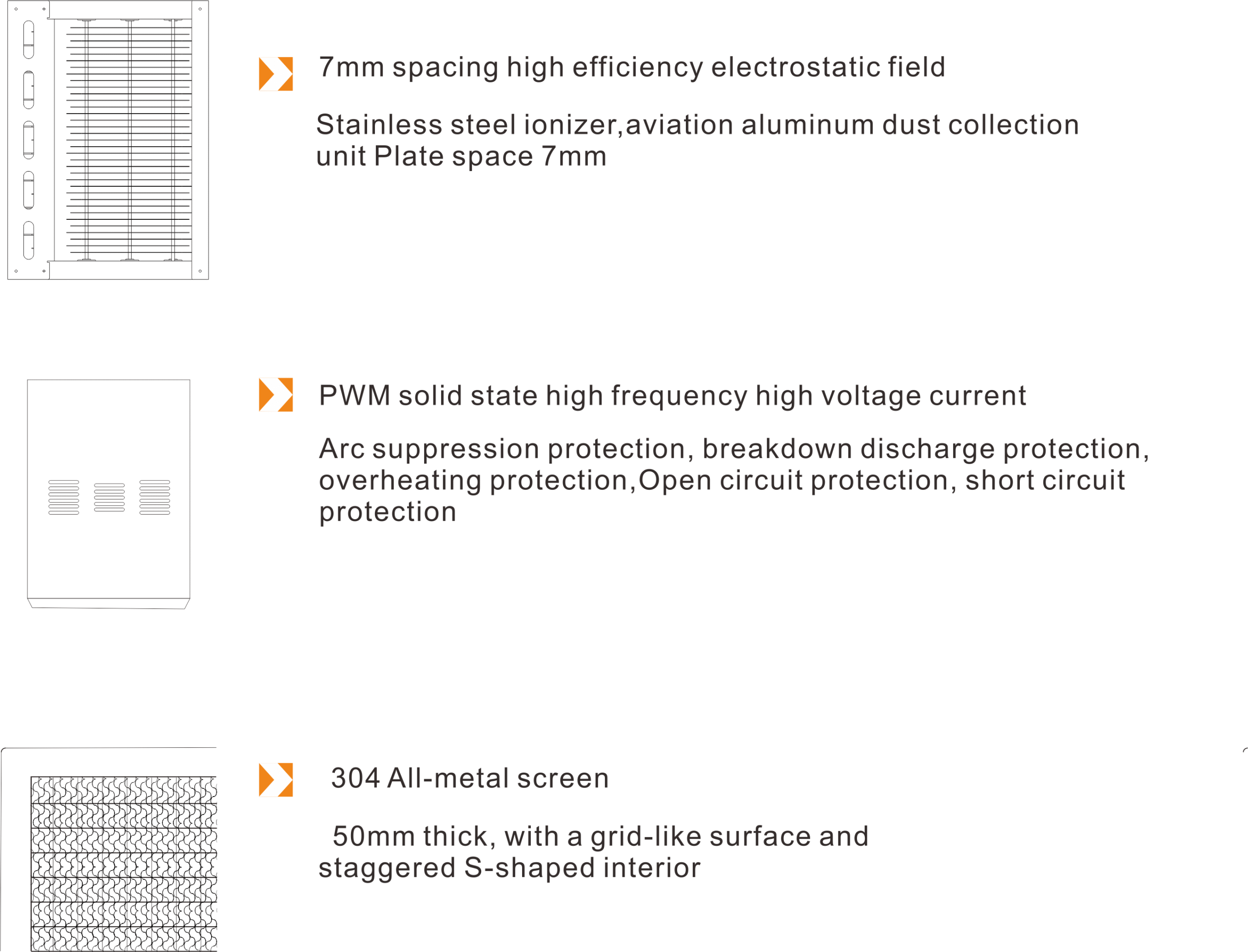

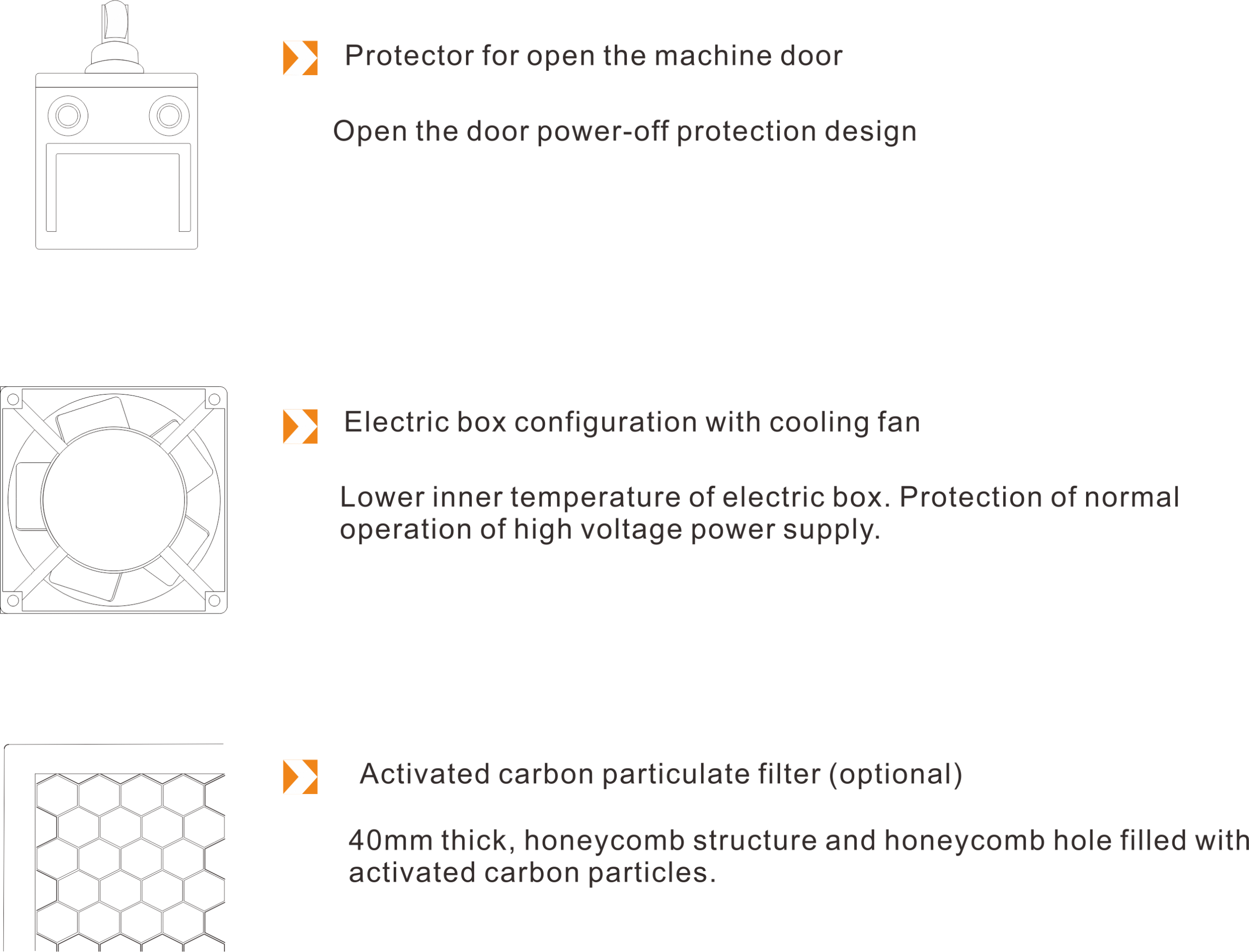

Product Configuration

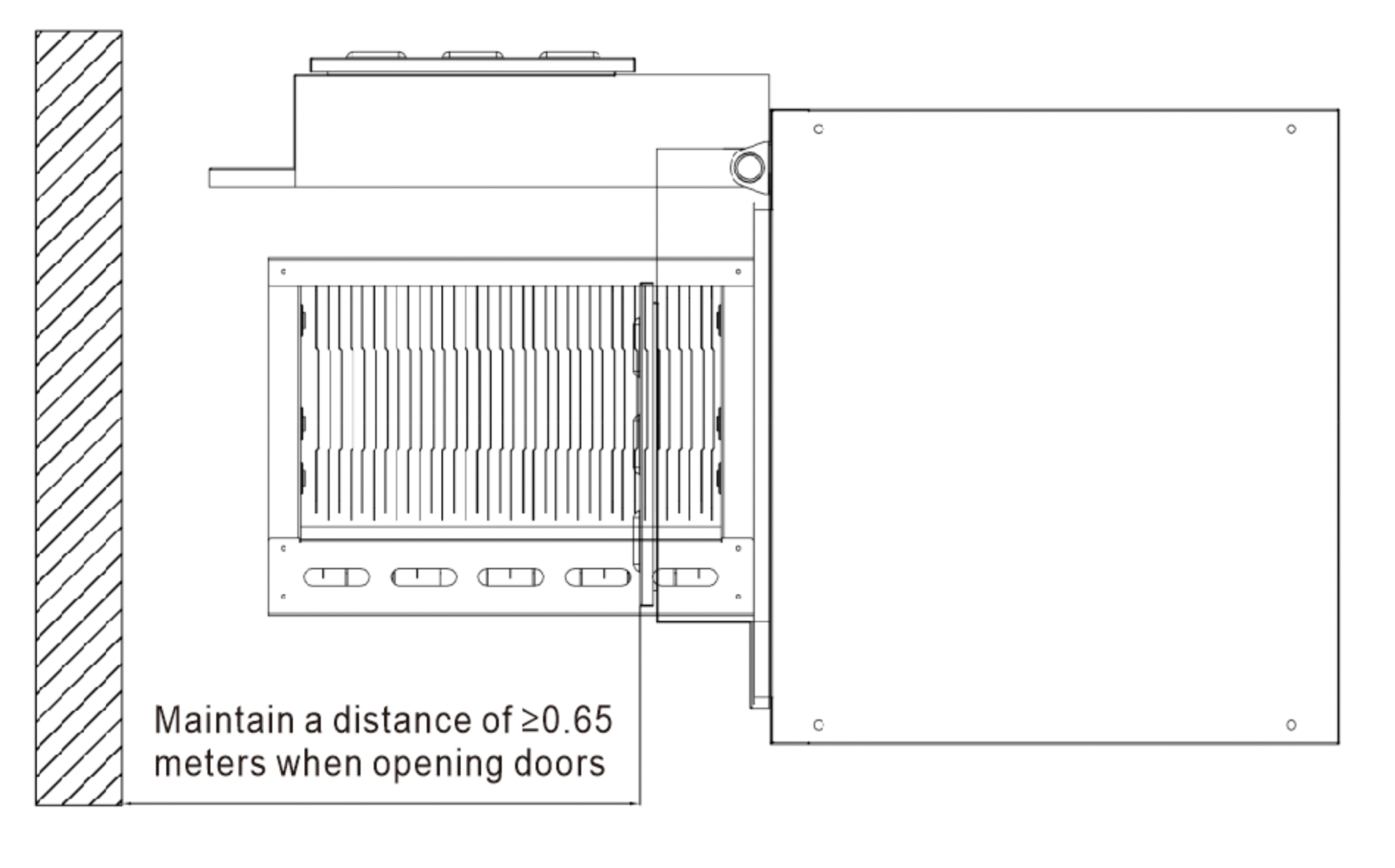

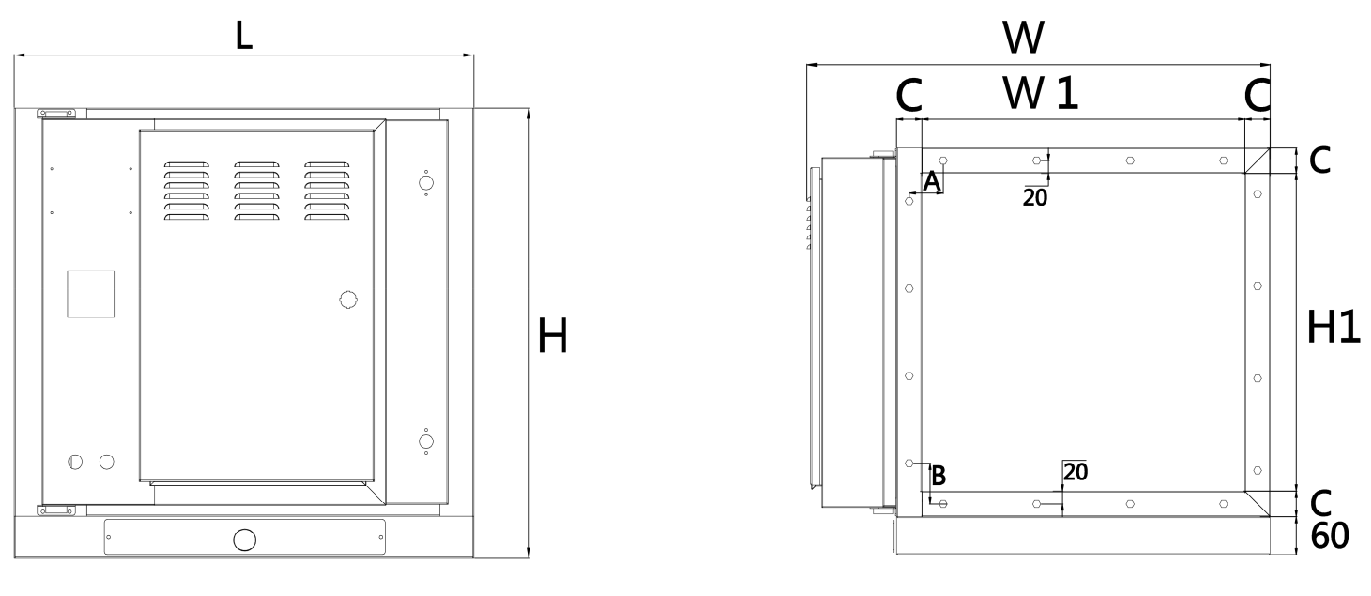

Installation space